Quick Turn PCB Assembly, 24 Hours Turn

What is Quick Turn PCB Assembly?

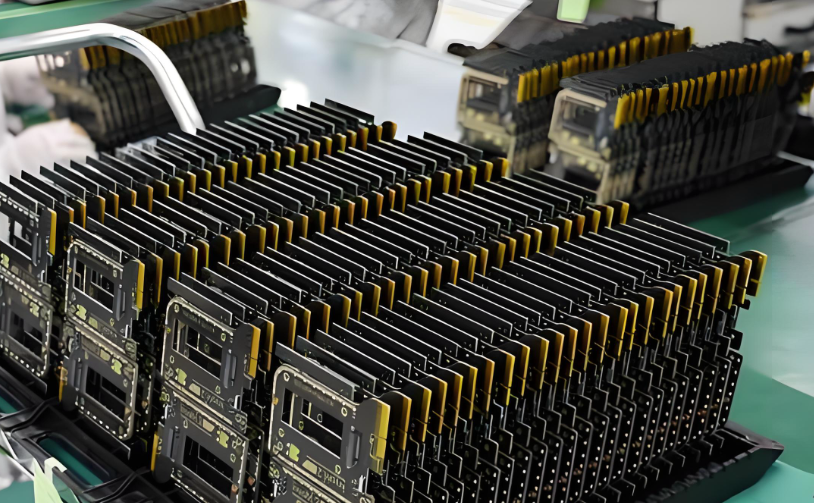

Quick turn PCB assembly is a streamlined manufacturing process designed to deliver fully assembled printed circuit boards (PCBs) in a significantly shorter time than standard production. In today’s electronics industry, speed is crucial. Companies must bring products to market faster, adapt to design changes, and respond to urgent orders. Quick turn PCB assembly addresses these needs by accelerating the entire process—from design verification to component sourcing, assembly, and testing—without compromising quality.

Unlike conventional PCB production, which may take weeks, quick turn assembly integrates automation, lean processes, and strategic inventory management to cut lead times dramatically. This approach ensures that urgent prototypes, pilot runs, or small-volume production can be completed in a matter of days, helping businesses reduce time-to-market while maintaining high reliability.

Types of Quick Turn PCB Assembly

Quick turn PCB assembly is usually categorized based on production volume. Understanding these categories helps companies select the most appropriate service for their project requirements.

- High Volume Quick Turn PCB Assembly

High volume quick turn PCB assembly is tailored for clients requiring thousands of units in a compressed timeframe. This is typical for consumer electronics, automotive, or telecom industries where delays can result in lost revenue or missed market opportunities.

High-volume quick turn assembly relies heavily on fully automated SMT (Surface Mount Technology) lines, inline AOI (Automated Optical Inspection), and sophisticated MES (Manufacturing Execution System) tracking to maintain speed and precision. At Best Technology, we optimize reflow profiles, pick-and-place sequences, and inspection protocols to ensure high-yield production even under tight schedules.

- Middle Volume Quick Turn PCB Assembly

Middle volume assembly serves as a bridge between prototype testing and full-scale production. These runs are typically in the hundreds to low-thousands range and are used for pilot products or limited series testing.

Industries like industrial electronics, LED lighting, and specialized machinery often rely on middle volume quick turn assembly to validate designs before committing to larger orders. Best Technology ensures flexible capacity allocation, rapid component sourcing, and synchronized assembly scheduling, enabling predictable delivery even with fluctuating requirements.

- Low Volume Quick Turn PCB Assembly

Low volume quick turn PCB assembly is primarily designed for prototypes or R&D units, usually ranging from 1 to 100 boards. Speed is paramount, as engineers need to iterate quickly based on testing and validation results.

Low-volume assembly requires agility to adapt to frequent design changes and immediate component adjustments. Best Technology supports same-day or 1–2 day assembly for select PCB types, coupled with fast BOM verification and in-house component sourcing to minimize downtime.

Benefits of Quick Turn PCB Assembly Orders

Quick turn PCB assembly offers more than just rapid delivery. It provides tangible advantages that can directly impact a company’s innovation and competitive positioning:

- Faster Time-to-Market: Reduces the development cycle, allowing products to reach customers sooner.

- Enhanced Design Validation: Enables rapid iteration and testing of prototypes to refine designs before mass production.

- Flexibility for Urgent Orders: Supports immediate modifications or emergency production needs.

- Cost Control: By avoiding delays in prototype testing or pilot runs, companies save on both production and operational costs.

- Reliable Quality: Automated inspection systems and process controls ensure that fast production does not compromise board quality.

What is Considered a Quick Turn for PCB Assembly?

The definition of “quick turn” varies by board complexity and order volume. Generally:

- 24 hours: Single- or double-sided prototype boards with straightforward SMT assembly.

- 3–5 days: Multi-layer or moderately complex boards with standard components.

- 5–7 days: Mixed-technology or medium-volume quick turn assembly.

At Best Technology, we consider a project “quick turn” if it meets these compressed schedules while maintaining quality, traceability, and consistency. Every order undergoes a pre-production review to verify feasibility and prevent delays.

Our Typical Turnaround Time for Quick Turn PCB Assembly

Turnaround time depends on board complexity, component availability, and volume. Typical timelines at Best Technology:

- Low Volume: 1–2 days for simple prototypes

- Middle Volume: 3–5 days for pilot or mid-size runs

- High Volume: 5–10 days for thousands of units with full testing

Our extensive component inventory, engineering review, and MES tracking allow us to reliably meet these timelines while maintaining high standards of quality.

Factors that Affect the Turnaround Time of a Prototype

The turnaround time for a PCB prototype is rarely fixed. While quick turn assembly aims to deliver boards in the shortest possible time, several critical factors can influence how fast a prototype can be completed. Prototype turnaround time is influenced by multiple interdependent factors, including:

1. Design Complexity – layers, density, and mixed technology

2. Component Availability – inventory, lead times, and sourcing reliability

3. File Preparation Accuracy – Gerber, BOM, and pick-and-place data

4. Testing Requirements – AOI, functional, and environmental testing

5. Revision Frequency – late changes and iteration loops

6. Production Capacity – machine availability, automation level, and scheduling

7. External Factors – shipping, special materials, or compliance demands

What is the Quick Turn PCB Assembly Process?

Quick Turn PCB Assembly is designed to deliver fully assembled printed circuit boards (PCBs) in the shortest possible time without compromising quality. The process is highly structured, combining automation, expert engineering, and efficient logistics to achieve rapid turnaround. The quick turn PCB assembly processes including:

Here’s a detailed step-by-step guide to the entire process:

1. Design File Review and DFM Analysis

The first step in any quick turn PCB assembly project is design verification. Engineers review all supplied files, including:

- Gerber files (copper layers, solder mask, silkscreen)

- Bill of Materials (BOM)

- Pick-and-place data

- Assembly drawings

During this stage, a Design for Manufacturability (DFM) analysis is performed. DFM ensures that the design can be assembled quickly and reliably. Any issues—like component spacing conflicts, incorrect pad sizes, or missing footprints—are flagged and corrected before production begins.

2. Material Procurement and Component Preparation

Once the design files are approved, the next step is component sourcing and preparation.

- Common or in-stock components are selected immediately from the manufacturer’s inventory.

- Rare or hard-to-source parts are ordered from trusted suppliers with expedited shipping options.

- Components are pre-taped, cut, or kitted according to the assembly requirements.

Having a well-organized component inventory and vendor network is essential for quick turn assembly. Delays in sourcing components are one of the main causes of extended lead times.

3. Stencil Fabrication and Solder Paste Printing

The next step is stencil preparation for solder paste application:

- A custom stainless steel stencil is cut for the specific PCB.

- Solder paste is precisely applied to pads using a stencil printer.

This step ensures that every component will adhere correctly during placement and soldering. Proper paste thickness and alignment are vital for avoiding defects like tombstoning, solder bridges, or cold joints.

4. Pick-and-Place Assembly

Once solder paste is applied, the pick-and-place machines mount components onto the PCB.

- Automated machines pick surface-mount devices (SMD) from reels or trays and place them on the board with high precision.

- Placement speed and accuracy are carefully calibrated to prevent misalignment, which is especially important for fine-pitch or dense layouts.

For quick turn PCB assembly, high-speed SMT lines are used to handle large or small volumes efficiently, ensuring that even complex boards can be assembled quickly.

5. Reflow Soldering

After components are placed, boards pass through a reflow oven:

- The oven heats the solder paste to its melting point, creating a solid, reliable solder joint.

- Temperature profiles are controlled precisely to prevent damage to sensitive components.

Reflow soldering is the step where the assembly starts to take its final form. For quick turn PCB assembly, optimized reflow profiles reduce process time without compromising the quality of solder joints.

6. Inspection and Quality Control

Quality control is integrated throughout the quick turn process. Post-reflow, the boards undergo multiple inspections:

- Automated Optical Inspection (AOI): Detects misaligned components, solder bridges, or missing parts.

- X-ray Inspection: Especially for BGAs or hidden joints, ensuring complete connectivity.

- Functional Testing (if required): Verifies that the PCB operates as intended under real-world conditions.

At Best Technology, every board is tracked via MES systems, providing traceability from component sourcing to final inspection. This ensures consistent quality even at accelerated speeds.

7. Final Assembly, Cleaning, and Packaging

After inspection, the boards are finalized:

- Through-hole components may be soldered manually or via selective soldering machines.

- Boards may undergo cleaning to remove flux residues or other contaminants.

- Protective coatings or conformal coatings are applied if required.

- Boards are carefully packaged in ESD-safe materials for safe shipping.

Efficient packaging and labeling are crucial in quick turn assembly to ensure boards reach customers on time and in perfect condition.

8. Delivery and Documentation

The last step involves shipping and documentation:

- Boards are shipped using fast logistics, sometimes with same-day or next-day delivery options.

- Detailed documentation, including assembly reports, inspection results, and traceability logs, is provided to the customer.

This final step ensures transparency, accountability, and peace of mind for clients relying on rapid PCB assembly.

Why Should You Choose Best Technology Circuit as Your Preferred Partner?

Best Technology Circuit offers one-stop quick turn PCB assembly solutions that combine speed, precision, and reliability. We handle low, middle, and high-volume orders across industries such as automotive, aerospace, medical, and consumer electronics.

Key advantages of partnering with us:

- Certified Quality: ISO9001, ISO13485, IATF16949, AS9100D

- Advanced Equipment: Automated SMT lines, AOI, and MES tracking systems

- Flexible Production: Capable of rapid response for urgent orders or complex prototypes

- Expert Engineering Support: DFM checks, BOM verification, and production optimization

- Competitive Pricing: Cost-effective solutions without sacrificing quality

When time is critical and precision matters, Best Technology is your trusted partner for reliable quick turn PCB assembly.

5 FAQs About Quick Turn PCB Assembly

1. How fast can a quick turn PCB assembly be completed?

A typical quick turn PCB assembly can be completed within 24 hours for simple prototypes, 3–5 days for medium complexity boards, and 5–10 days for high-volume or complex assemblies.

2. What is the difference between low, middle, and high-volume quick turn PCB assembly?

- Low volume: 1–100 units, ideal for prototypes or R&D

- Middle volume: Hundreds to low-thousands, suitable for pilot runs

- High volume: Thousands of units, designed for urgent mass production

3. Can quick turn PCB assembly maintain high quality despite faster turnaround?

Yes. Modern quick turn processes use automated SMT, AOI, and MES systems to ensure consistent quality, even for fast deliveries.

4. What factors can delay a quick turn PCB assembly order?

Delays are typically caused by component availability, design complexity, frequent revisions, or extensive testing requirements. Proper DFM review and pre-sourced components minimize these risks.

5. Why choose Best Technology for quick turn PCB assembly?

Best Technology combines speed, precision, and reliability with certified quality (ISO9001, ISO13485, IATF16949, AS9100D), advanced equipment, flexible production, and expert engineering support, making us a trusted partner for rapid PCB assembly projects.

language

language